Roll fed type paper bag making machine

Product advantages

- High productivityProduce On the machine directly after rotary painting with high productivity, which effectively saves the cost of intermediate links and human labor.

- High stabilityThe mechanical parts comply the standards ofJIS (Japanese Industrial Standards), and we cooperate with world-class manufacturers such as Schneider, Mitsubishi, Nordsen forthe

Electrical parts, which both ensure our machine the capability of 24 hours uninterrupted producing and a long service life.

- Continuously variable Cutting deviceBesides changing the speed freely, achievethe goal of accurate positioning, Fast model changing and low consumption by using two servomechanism to drive and

combining with PLC control process.

Technical parameters

|

DTF360M-B76 |

DTF460M-B95 |

DTF600M-B133 |

| paper bag width |

210-360 mm |

260-460 mm |

400-600 mm |

| bag bottom width |

70-150 mm |

70-180 mm |

100-230 mm |

| sheet width |

590-1050 mm |

690-1260 mm |

1070-1630 mm |

| sheet length |

340-600 mm |

380-600 mm |

520-800 mm |

| tube length |

280-540 mm |

320-540 mm |

460-740 mm |

| handle length |

152.4 mm |

188.5 mm |

266.7 mm |

| handle paper width |

80-90 mm |

80-90 mm |

90-100 mm |

| string pitch |

76.2 mm |

94.2 mm |

133.35 mm |

| string height |

170-180 mm |

170-180 mm |

170-180 mm |

| top folding |

40-60 mm |

40-60 mm |

50-60 mm |

| power consumption |

15 KVA |

18 KVA |

22 KVA |

| working speed |

45-80 pcs/min |

40-70 pcs/min |

40-60 pcs/min |

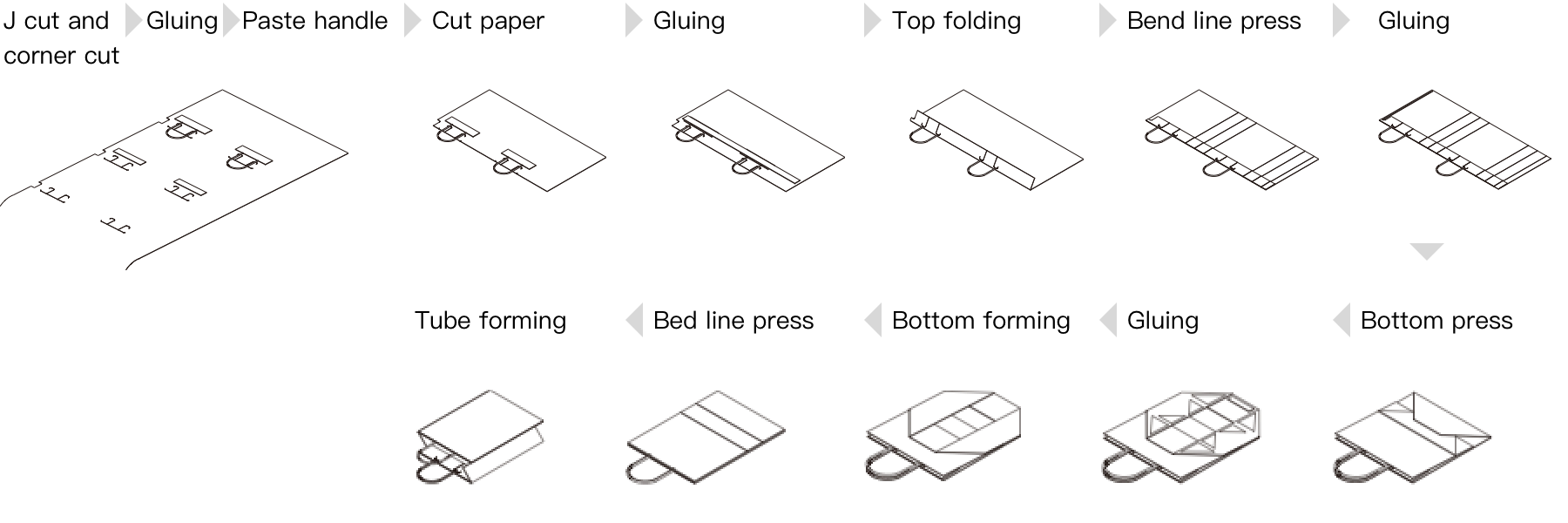

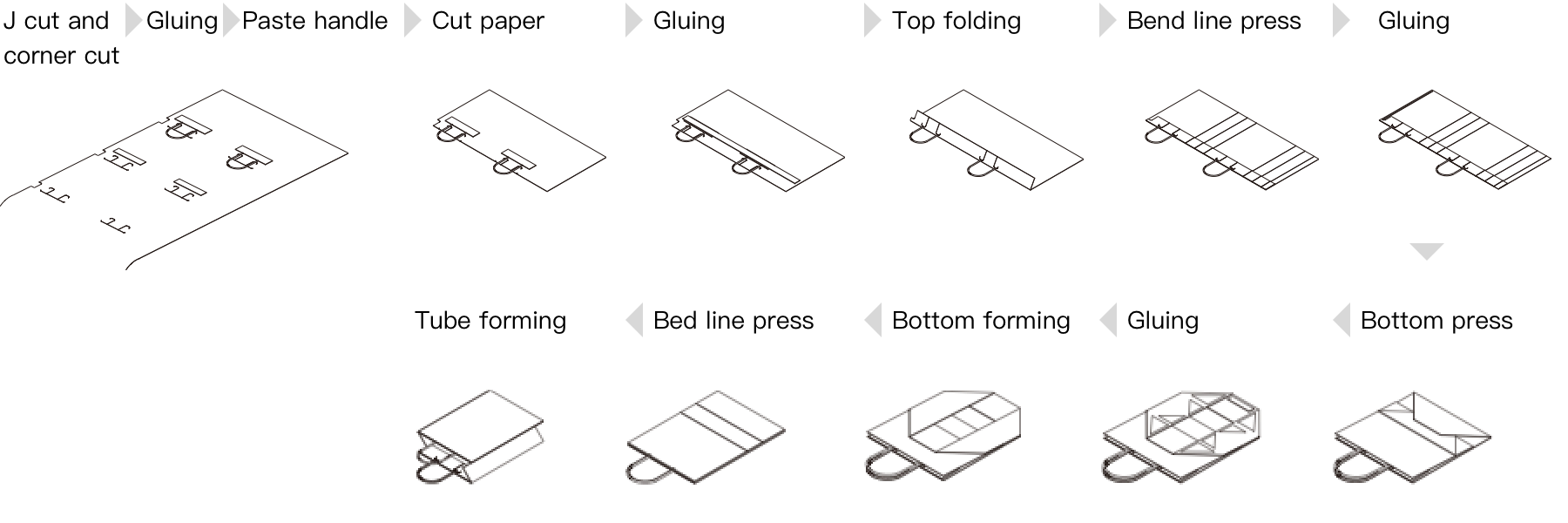

Process flow